A few years ago J and I took scratch-built RC boats and sputtered around a pond-fountain near J’s house for loads of shits and giggles. This year we are doing RC boats again! Hopefully there will be more giggles and less shits this time around.

This is the Titanic. I call it the Titanic because the hull is actually from an approximately 1:350 scale model of said ship. When I was very young, I bought the kit at my (now long defunct) local hobby shop but putting it together at that age was obviously disastrous. Over the years, the rest of the ship has gradually been torn up and discarded, but just getting the hull has probably been well worth the $60 I paid for the entire kit.

The actual RC equipment was from a similar venture from around the same time. That was a kit RC tugboat that I screwed up just as badly. The motor is from some Tamiya kit (I think it’s like solar-powered dragonflies); it’s actually a pretty decent piece of kit, unlike some of the more rubbish motors that commonly come with Tamiya sets. Most of the random bits that comprise the ship have similar histories: the aluminum sheet that I use to make some brackets is actually a leftover from high school robotics. Meccano nuts and bolts make great fasteners.

Construction of the ship also took place over a very long period of time. I think I first seriously considered finally making a working RC boat again sometime in junior high or high school, several years after I failed to make the tugboat work. I don’t know what sparked it, and I don’t really know how I went about it, but the first version must not have been very good. For a couple years after, I’d brush it off every summer, tweak it a little (in theory for the better), and take it out for a spin. Obviously this stopped after I stopped swimming, but not before the original configuration had deteriorated pretty badly.

The hull obviously did not originally have a hole in the stern for a “real” propeller shaft, so with my admittedly primitive tools, I put one through in a pretty bad way. By Titanic’s last season (probably summer between junior and senior year of high school), the amount of water she was taking on through that “seal” was so bad, I installed a bulkhead between the “engine compartment” and the rest of the ship such that I didn’t have to drain the hull every five or ten minutes. Much of the electrics were also original and, while tidied considerably over the life of the ship, had also corroded accordingly.

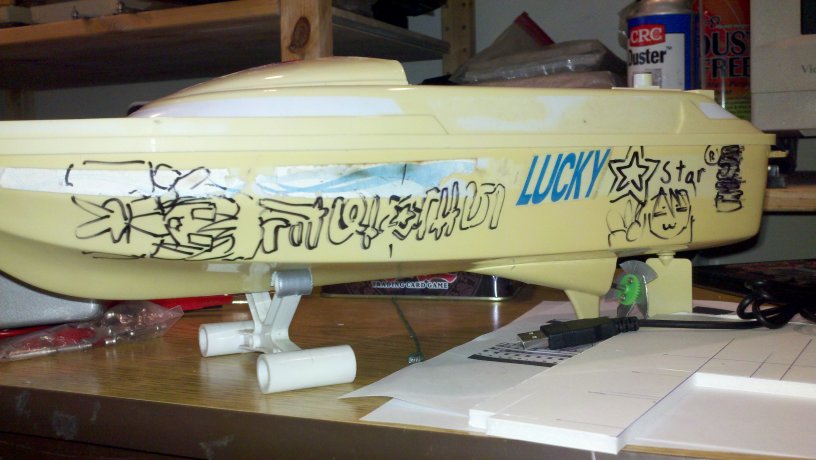

Titanic was in such bad shape that, when J and I did RC boats a few years ago, I opted not to use her hull and mechanical components and built my other boat, Lucky Channel. Unfortunately, I also broke Lucky Channel, so for round two it was time to bring the Titanic back.

The Titanic, of course, required a complete rebuild. Now that I think about it, I should have taken “before” pictures. Basically I wanted to replace all the glued, wooden mounting points in the ship (for servos, motors, etc) with bolted plastic or metal. I also wanted to rewire all of the standing electronics (like not the removable servos or controller) such that I could drive everything from a single set of batteries (four D cells now), and such that I wasn’t dropping one or two volts from bad contacts just trying to get power from source to motor.

So far it looks like the rebuild has been fairly successful, but it will be hard to say for sure until I actually get some water mileage that’s not in my tub. The battery and steering servo are now bolted to the plastic hull with a combination of metal and plastic bits that I made over the last two days. The drive motor is fastened with metal brackets made in the last rebuild (when I installed the bulkhead), and the switch assembly, my current stand-in for an ESC, is still an original part, with only a little modification.

If there’s anything I’ve gotten really good at apparently, it’s making small parts out of thick wire and, in general, making really ghetto parts such that I don’t have to buy anything. I also plugged a lot of leaks, including the nasty one for the propeller shaft. There was also a gaping hole that had been left by breaking out a stubbornly glued wood fixture during the last rebuild: it was a roughly two square centimeter gap, which had previously been patched with duct tape. I did something (hopefully) better with super glue, plastic sheet, and Testor’s version of bondo.

There’s also small fixes like sanding out the inside of the hull, a new rudder shaft, maybe even a new paint job in the future, and so on.

Eventually I was happy enough with the mechanical rebuild (even if it’s not quite done yet) such that I decided to make some cosmetic improvements. The cutout of the Titanic’s superstructure is a fairly straightforward sandwich of packing tape, paper, and foamcore. I almost wanted to actually try to build something substantial, but after giving it some thought, I decided I really just wanted something to break the monotony of having just a big black hull – it could have been any superstructure, I just thought this one appropriate. It really just needs to suggest the Titanic; any hope of a more detailed model died a long time ago.

That’s all for now. More thoughts once we can get it on the water.